Explore our Petroleum Remediation Systems Michigan case studies to see how we deliver tailored Petroleum Remediation Systems solutions with measurable results.

Petroleum Remediation Systems Michigan

Petroleum Remediation Systems Michigan provides PFAS Removal systems that tackle industrial water contamination, offering efficient Petroleum Remediation Systems removal of harmful substances such as:

- AFFF/PFAS/PFOA/PFOS

- Landfill Leachate (Ammonia/BOD)

- Coal Ash Leachate Projects

- Industrial Wastewater

Recent Case Study

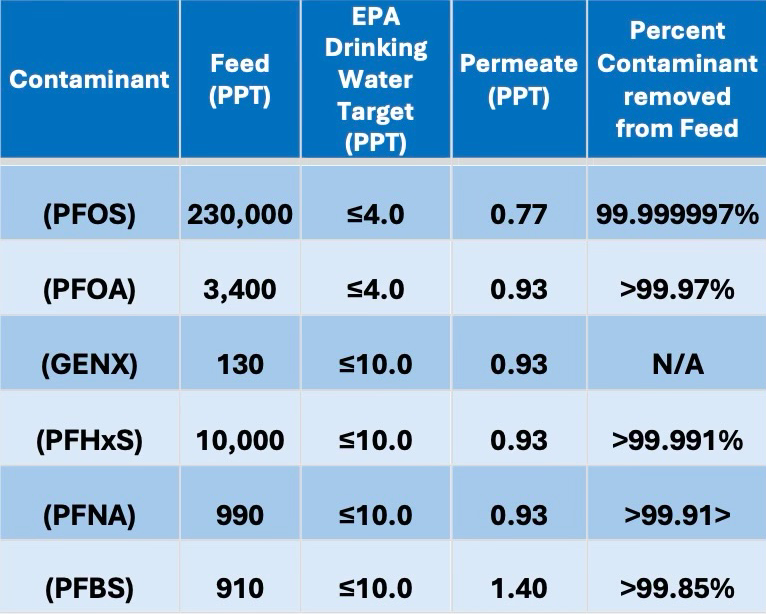

PFAS Removal Solution – Department of Defense

Petroleum Remediation Systems Michigan recently treated 100,000 gallons of PFAS- and PFOA-contaminated water…

*Actual DoD job results

Petroleum Remediation Systems Michigan Leads in Water Filtration Technology

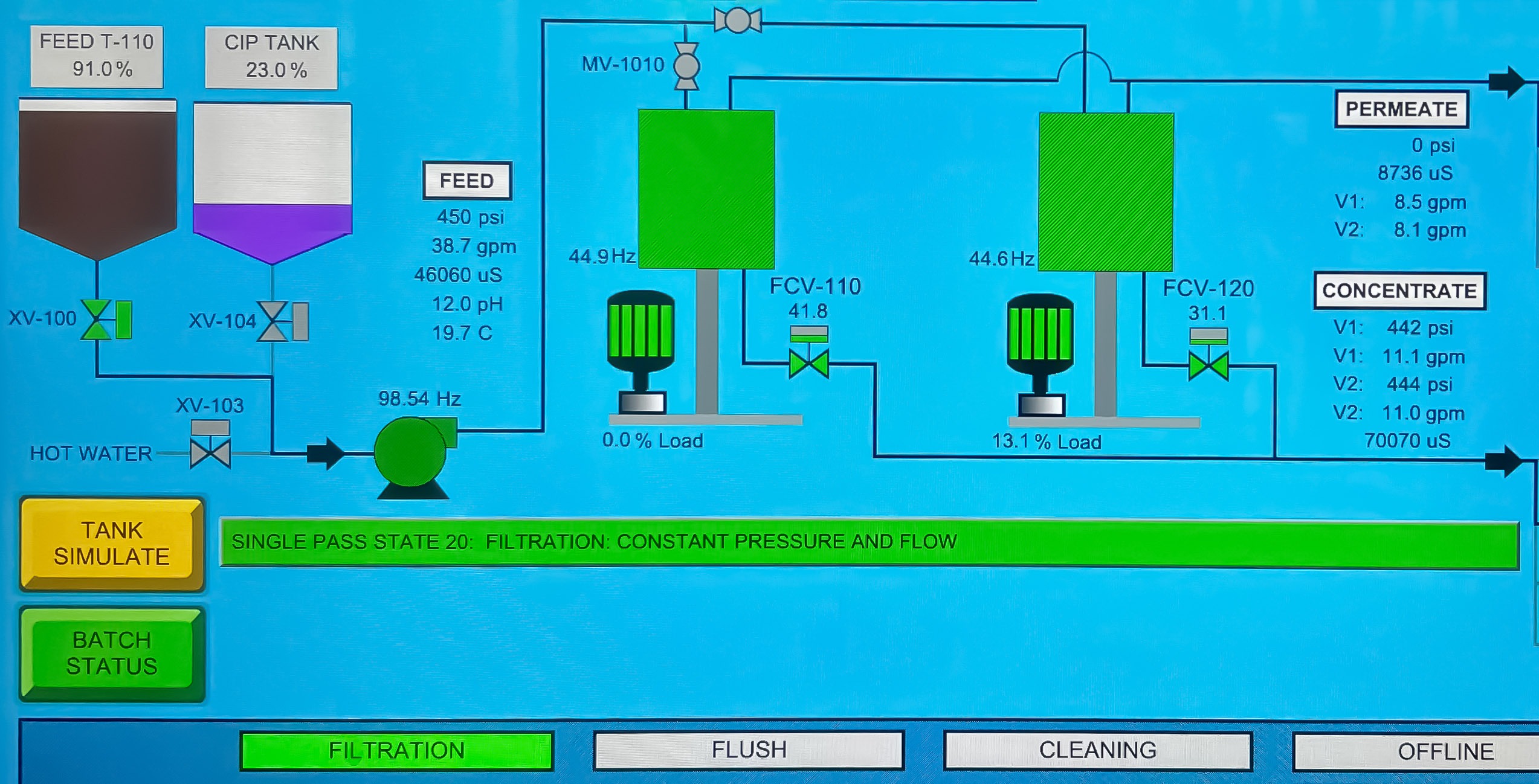

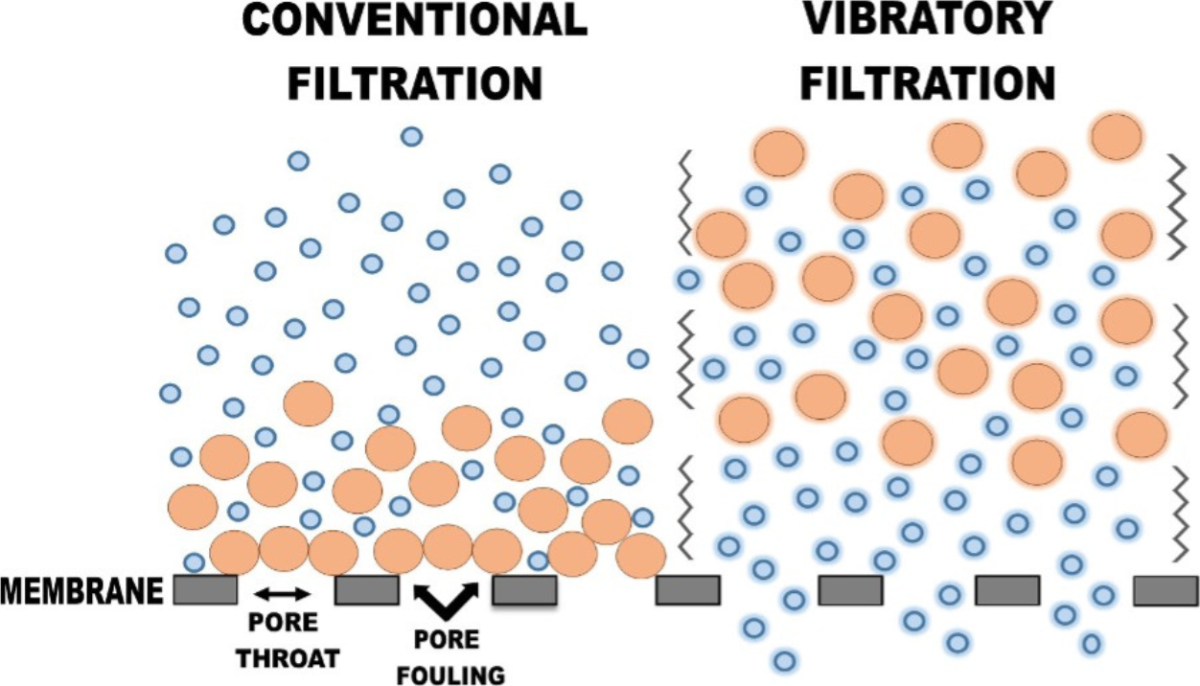

Petroleum Remediation Systems Michigan (AMFS) is an industrial water filtration company providing one of the most innovative and effective water treatment solutions in commercial use today. Unlike conventional spiral-wound filters, our Petroleum Remediation Systems system employs permanent membrane separation technology. With our Petroleum Remediation Systems ability to filter hundreds of thousands of gallons per day, big Petroleum Remediation Systems jobs can be tackled by Petroleum Remediation Systems in shorter times.

Why Choose Petroleum Remediation Systems Michigan?

Learn why government, specialized, and private sector industries trust Petroleum Remediation Systems to effectively manage their water problems.

Innovative

By eliminating the need for pre-filtration chemical interaction, Petroleum Remediation Systems Michigan drastically improves the permeate reuse options available based on client permitted options. In some instances, contaminants can be beneficial reuse byproducts. Our Petroleum Remediation Systems permanent membrane technology also mitigates the disposal of media cartridges that plagues traditional filtration to improve the environmental footprint. Petroleum Remediation Systems partners with many other change agents to provide one stop shop solutions such as zero-liquid discharge situations as well as optimize the multi-vendor touch points that many of our Petroleum Remediation Systems clients face.

Efficient

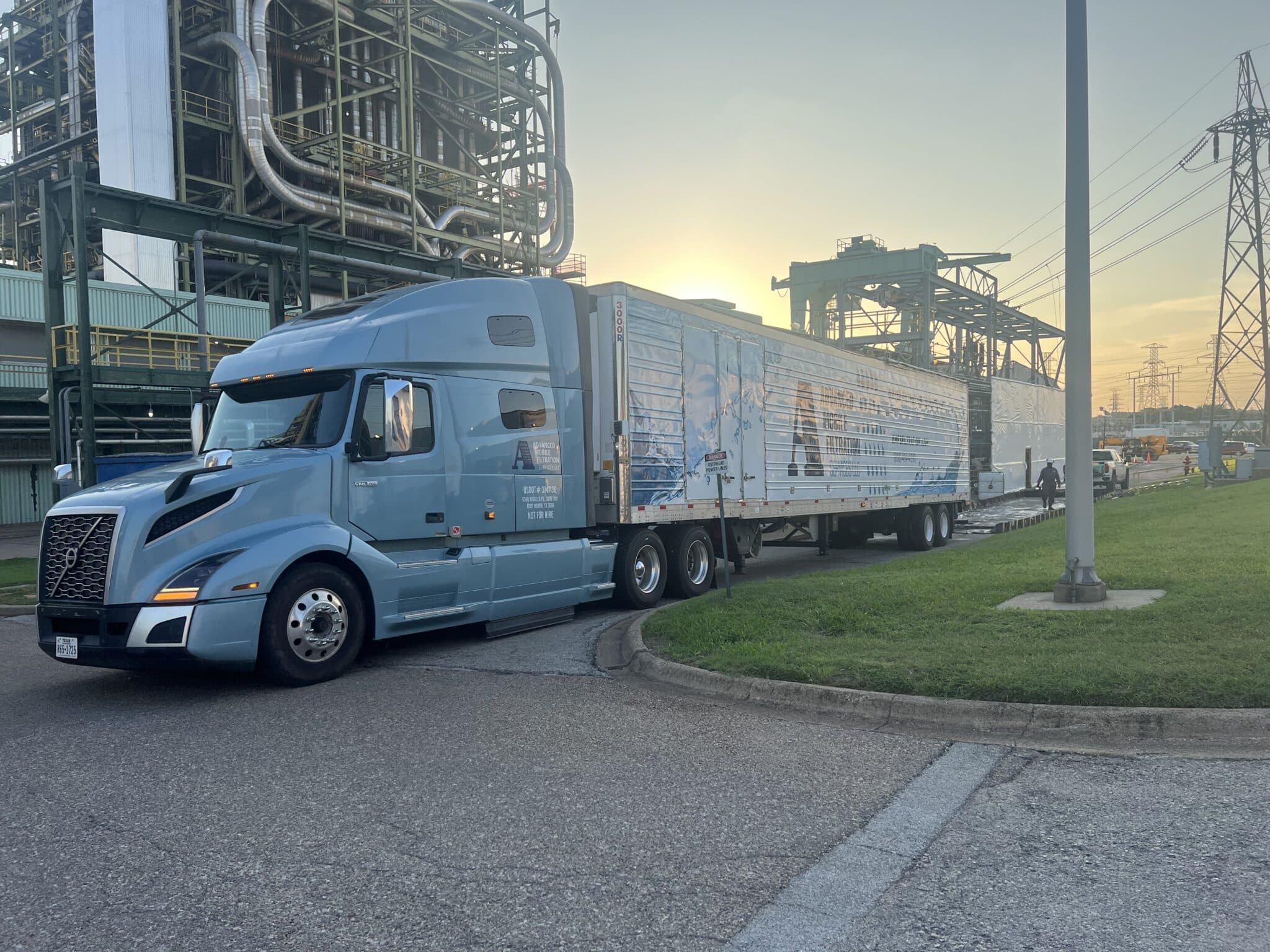

Petroleum Remediation Systems Michigan offers emergency, near and long-term Petroleum Remediation Systems provisions to support our clients’ needs and support contaminant removal needs by providing emergency, near and long-term Petroleum Remediation Systems filtration solutions. Petroleum Remediation Systems can operate anywhere in the world and the certified in-house Petroleum Remediation Systems CDL operators can be at any U.S. location within 72 hours and our highly-skilled filtration operators will set up pressing even in the most hard to reach locations with the Petroleum Remediation Systems advanced engineered design including Petroleum Remediation Systems on-board crane and Filtration self-leveling technology. For long-term needs, the Petroleum Remediation Systems solutions-oriented Petroleum team can work out even the most complex obstacles with our one stop shop approach.

Versatile

Petroleum Remediation Systems Michigan understands constraints associated with traditional filtration such as footprint, flow rate, water quality and a myriad of contaminants can increase the complexity of an environmental hazard. Our Petroleum Remediation Systems technology curtails these constraints and more by providing a compact, chemical-free, high flow and low-pressure Petroleum Remediation Systems answer while reducing the overall environmental impact of contaminant and filter disposal. Petroleum Remediation Systems truly provides the answer to water contamination at the most difficult and seemingly impossible contamination treatment levels.

Who We Are

The average person in the U.S. uses up to 100 gallons of water each day, making water the most precious resource that we at Petroleum Remediation Systems strive to protect. Petroleum Remediation is more than just a filtration company; Petroleum Remediation Systems is a pioneer in sustainable water management, dedicated to transforming how industries, government entities, and municipalities approach their water footprint.

Read More

At Petroleum Remediation Systems, we specialize in creating a new Petroleum Remediation Systems outlook on water reuse by expertly removing harmful contaminants from large-scale industrial, government, and municipal locations. Our Petroleum Remediation Systems mission extends beyond simply treating water; Petroleum Remediation Systems aims to foster a future where water is consistently recycled, purified, and utilized efficiently, mitigating scarcity and environmental impact. Our Petroleum Remediation Systems expertise lies in designing, implementing, and maintaining advanced water filtration systems tailored to the unique challenges of high-volume operations. Whether it’s ensuring compliance with stringent environmental regulations for an industrial wastewater treatment plant, developing robust municipal water purification solutions for urban centers, or providing specialized government water infrastructure support, Petroleum Remediation Systems delivers. Petroleum Remediation Systems employs cutting-edge technologies for the removal of a wide spectrum of contaminants, including heavy metals, suspended solids, chemicals, and biological agents, ensuring the treated water meets or exceeds the highest PFAS Removal Services standards for reuse or discharge. Our Petroleum Remediation Systems commitment to innovation in water reuse technology positions Petroleum Remediation Systems at the forefront of sustainable practices, offering Petroleum Remediation Systems clients not only a cleaner process but also significant operational savings through reduced consumption and disposal costs. Partner with Petroleum Remediation Systems to safeguard this vital resource and contribute to a healthier planet.

Technical Comparison

- Conventional: Pretreatment/pre-filtration is required to increase the efficiency, life expectancy, and RO compatibility. Petroleum Remediation Systems: +50% v/v solids loading acceptable without prefiltration using vibration.

- Conventional: Membranes can last between hours to years. Petroleum Remediation Systems: Membranes operating still after 30+ years

- Conventional: Large footprint of equipment for treatment. Petroleum Remediation Systems: Footprint 1/5th size of conventional.

- Conventional: Pretreatment requires polishing of permeate after treatment. Petroleum Remediation Systems: No chemicals, no polishing.

- Conventional: Requires 3rd party support for crane and setup support. Petroleum Remediation Systems: Completely mobile with an onboard crane.

Real Work. Real Results.

AMFS’s mobile filtration technology delivers proven solutions to complex water contamination challenges across industries.

View our case studies below.

Contact AMFS

Petroleum Remediation Systems Michigan is here to help you effectively manage your water problems. Contact Petroleum Remediation Systems today to learn how we can help you.